When manufacturing organizations integrated coordinate measuring machines within their processes in the 1960’s, their main objective was to inspect manufactured products to ensure that key dimensions were within their specifications. Thirty years later, point-cloud scanning technologies emerged and made it possible to quickly digitize and analyze tooling, prototype pieces, and pilot assemblies to reduce time to market while engineering a new product. Today, as we have successfully integrated dimensional analysis and quality control workflows within a single solution, you can now deploy a common 3D measurement platform for your entire product engineering and manufacturing lifecycle.

Article

Unify Your 3D Metrology Operations With a Universal Software Platform

Today, manufacturing companies have sophisticated 3D measurement labs with portable and CNC CMMs, laser scanners, laser trackers, and digital gauges, with every brand of hardware using their own software solutions. When relying on multiple software programs, multiple workflows must be mastered, which hinders the performance of 3D measurement teams. Replacing those software with a universal software platform addresses the struggles of measurement teams and significantly increases 3D metrology operational efficiency.

Article

Mixed Reality: The Most Significant Advance in Large-Scale 3D Metrology Since the Laser Tracker

Emerging mixed reality technology is transforming large-scale metrology, optimizing the benefits of laser trackers, and offering the same benefits as projectors and remote controls while exceeding their limitations. Among the formidable new capabilities of smart glasses together with powerful 3D measurement software are guidance graphics and measurement instructions superimposed on the measured piece, ensuring operators always measure the right features and obtain real-time measurement feedback.

White Paper

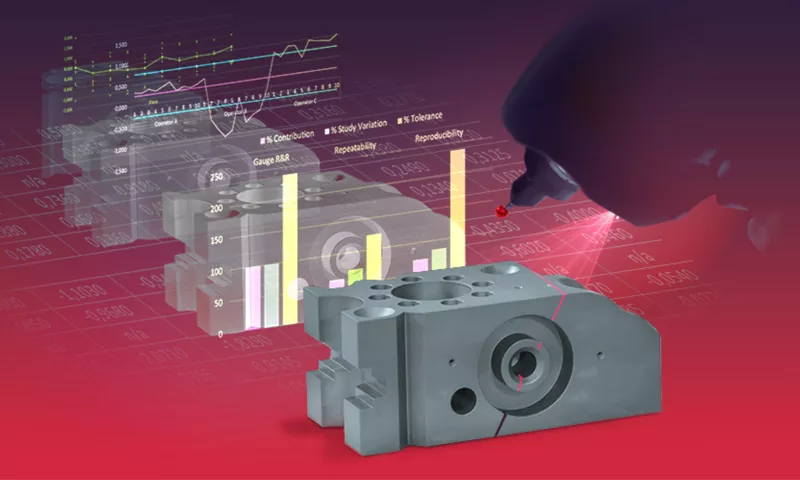

Collecting Trustworthy 3D Measurements

The Smart 3D Metrology Approach

Metrologists know that measurement systems aren't perfect. By performing a Measurement System Analysis (MSA), you can identify the components of variation in your measurement process and take corrective measures to ensure it represents no more than 30% of measured deviations.